Media Blasting Comparison

There are several different types of media that can be used to blast clean surfaces. Each one has different advantages and disadvantages. This table shows a handful of criteria for comparison which are explained in more depth below. At Iceberg Dry Ice we want you to use the right tool for the right job and when a different media would be more effective for your job we are happy to help find you the right solution.| Media | Mose | Clean Up | Advantages | Disadvantages |

|---|---|---|---|---|

| Dry Ice | Soft | 0 lbs. | Cold, Thermal Shock, Environmentally Friendly | Oxygen Displacement |

| Soda | Soft | 450 lbs. | Buffers Smoke Smell | |

| Walnut Shells, Corn Cobs, Sponge, Plastic Bead | Medium | 1800 lbs. | ||

| Coal Slag, Glass | Hard | 1800 lbs. | ||

| Water | Med-Hard | 1800 L | Inexpensive | Mould, Conductive |

| Silica Sand | Hard | 1800 lbs. | Carcinogenic | |

| Solvents | Soft | special | Environmentally UNfriendly |

This is what type of media you are propelling at your cleaning surface. Silica sand can't be used anymore because it has been deemed carcinogenic by WorkSafe BC.

The Mose scale is used to rate hardness with talc being a 1, and diamonds being a 10. The harder the media the more aggressive it is in cleaning and the more damage it does to your surface. Hard media like glass and coal slag can pit metals and will destroy wood but because of this they can clean rust or do cement finishing. Softer media like dry ice and soda won't effect cement, but they can be used on wood finising, or circuit boards safely.

Fryability is a measure of how easily the media breaks apart. Dry ice and soda are highly fryable which means that instead of causing damage to your surfaces, they disintegrate on contact. This is why they are referred to as no-touch or non-aggressive cleaning techniques, and why they are used to restore masonry and clean wooden structures without impacting their structure.

Assuming 6.5 hours of trigger time in a standard day how much media will be lieing around on the ground? Medium and hard medias are consumed at a rate of 5-6 lbs. every minute, dry ice at about 3 lbs. every minute, and soda at about 1.5 lbs. every minute. Dry ice sublimates (changes directly from a solid physical state to a gas) and disappears, leaving nothing to clean up but the contaminant you've removed. This is a very large factor to consider as it takes a lot of time to clean up the resulting media, and it may have to be disposed of if the contaminant is dangerous.

Cold - dry ice is -78.5 celcius, and sticky substances like glue, tar, ink etc. are cleaned very

effectively because the contaminant is frozen and then chips off!

Thermal Shock - dry ice will cause the surface and contaminant

to change temperature at different rates causing a micro-thermal shock. This helps to pull them apart

so cleaning is more effective.

Environmentally Friendly - dry ice is made from recycled carbon dioxide and exists naturally in the

atmosphere. Because of this it is a very green solution!

Buffers Smoke Smell - soda works as a strong buffer for acids and bases, because of this the smell of

smoke is greatly reduced in fire restoration work.

Inexpensive - power washing saves money as no specialized media is needed

Oxygen Displacement - dry ice is made from carbon dioxide which will displace

oxygen at a rate of ~ 800 cubic feet per hour. As a result, additional PPE (personal protective equipment) is required

if the work is being done in an enclosed space.

Mould - the water from power washing can cause mould issues if used indoors.

Conductive - water is electrically conductive unlike other blasting media.

Environmentally UNfriendly - solvents can be very toxic which is a great reason to use dry ice

blasting instead.

How Blasting Works

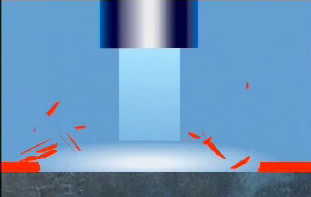

Dry ice blasting is similar to power washing or sand blasting except it uses

dry ice instead of water or sand respectively. When the ice hits the cleaning

surface several things happen.

Dry ice blasting is similar to power washing or sand blasting except it uses

dry ice instead of water or sand respectively. When the ice hits the cleaning

surface several things happen.1. The dry ice particles immediately sublimate on contact by sucking some heat from the target. The surface cools slightly causing a small pressure wave that helps lift the dirt off like a spatula. This is called a micro-thermal shock.

2. When dry ice sublimates it expands from a solid to a gas taking up 600 x as much volume. As you blast, the dry ice slips under the surface layer of dirt and then expands, causing a tremendous lifting force that cleans your target.

3. Because dry ice is extremely cold ( -78.5 C ) it proves more effective against adhesives by freezing them so they will chip off more easily.

Because of the above benefits dry ice is much more effective in specialized projects. When under time constraints dry ice is very beneficial because there is no clean up, the dry ice simply sublimates into a gaseous form and disappears.

Dry Ice Blasting Advantages

Dry Ice has many unique properties that make it the right choice for certain applications. Read about them below and see how it is already used to decide if blsating is the right choice for you.Dry ice sublimates directly into a gaseous state leaving no residue behind like the other blasting solutions. Because of this there is no cleanup needed and jobs can be completed in a much shorter time. This is very beneficial when you need to keep your surfaces water free to prevent rust or mold, or in the event of machinery like printing presses where you can't afford to have sand particles left behind.

Carbon Dioxide is the 4th most abundant gas found naturally in the atmosphere, it's everywhere! Dry ice (solid carbon dioxide) is a fantastic solution when your only other alternative could be toxic cleaning chemicals. Because it is created from reclaimed carbon dioxide, it doesn't add anything to the atmosphere and so doesn't contribute to the greenhouse effect.

Dry ice does not conduct electricity and can be used to clean machines, and electrical systems while they are still running! Because of this you won't need to even turn your systems off and lose any time on production.

Dry ice is extremely cold ( -78.5 C ) which helps it remove glue like substances, graffiti, oils, and the like. The dry ice freezes the glue making it chip off much easier then using other media which would get stuck.

Dry Ice blasting doesn't abrade surfaces like power washing or sand blasting. Because of this it won't ruin finishes, layers of paint, or leave deep blasting groves on your walls.

Dry ice blasters are portable and the hoses to the gun can reach 50 feet or longer. This allows you to clean equipment in place, preventing downtime and the need for a dedicated cleaning room.

Dry ice blasters use food grade carbon dioxide and have been approved by the EPA, FDA, and USDA making them safe for cleaning kitchens, food processors and the like. Because dry ice is so cold it kills bacteria and fungi on contact, disinfecting without the use of any chemicals.

Blasting with dry ice is substantially faster and cleans better then conventional scrubbing. In addition no chemicals or cleaners are used so it's more environmentally friendly.